1. 1. “CHPP #4” SOJSC has been successfully implementing the MON-P10 project funded by the Japanese Government’s soft loan since 2014 to improve the reliability of the main components and to increase the economic efficiency of the company.

During the project, the modernization of the existing regulation system of the steam turbines (TA №1-6) to an electrical hydraulic regulation, the shifting of the control system to DCS system, the installment of soot blower, and, also upgrading of the mill roller of the coal pulverizer in the total 8 boilers had been done. As the result of the implementation of the project, damages on the heating surfaces of the boilers will be reduced, and the O&M costs will be decreased due to increased non-stop operating hours. The replacement of the old control system to the DCS system will provide a way for a centralized control system for the boilers as well as for the turbines.

2. The ash dump no.7 with the volume of the 830,000 m3 were expanded by constructing or rather elevating of the dam using its disposed ash with the HAS technology from 2017 to 2018 and put into operation. The technological solution enabled to save MNT 2.0 billion compared to the conventional construction technology and also avoids 137,987.5 m3 of sand and gravel, which has an environmental significance and prevents soil erosion.

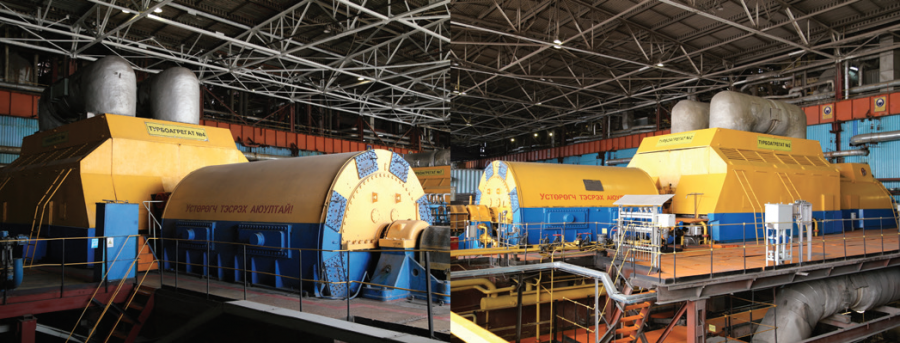

3. The project for “The renovation of the turbine generators №1, 2, 3, 4” funded by Russian Government’s soft loan has being implemented from 2018 to 2020. The EPC contractor of the project, Russian turbine manufacturer “The Ural turbine works”, will complete the work within the regular maintenances period of the plant. As a result of the project, the following parameters will be improved:

- Turbine operation time increase by 220,000 hours,

- Installed capacity of the plant increase by 89 MW,

- Turbine’s heat load increase by 97 Gcal/h,

- Turbine’s efficiency improves between 2.5% and 3.0%.

- Operation of both generator and transformer will have been not limited by their capacity

- The reliability of the main components will be improved.

- 100,000 tonnes of coal will be saved annually.

2. 1. During 2017-2018, with the investment of MNT 6 billion from the State budget, “Erdenet CHPP” had expanded the dump's no.2 capacity by 565.0 m3 with the measures such as elevation of dam and loosening of the ash. Thereby, it increased operational time of the ash dump by 4.5 to 6 years.

2. The central heat control station no. 1 was updated to the smart control station by means of transferring of the boilers’ (no.1-4) I&C to the computer monitoring and control system. That allows to transfer and record technical and economical primary parameters and data of the plant without any delay.

3. 1. “Eastern electric power system” SOJSC has updated their control systems of turbine generators No. 3, 4 and auxiliary components to the computer based technical control and monitoring system.

2. Within the upgrading work of the 35 kV overhead transmission line in Bulgan province, several replacements have been done, e.g. the new 35/15 kV, 10 kVA transformers, 38.2 km long AC-50 uninsulated wire by AC-70 wire, old wooden power poles from 1985 have been replaced with 227 steel concrete poles and 16 towers.

3. The condenser tube cleaning system that manufactured in Taprogge from Germany, has been installed for turbine condensers No. 1, 2, 3 and 4. The condenser (vacuum) parameters of 11 month after installation have been improved by 4.2 percent that resulted in preventing of burning of 8,404.4 tonnes of coal with market value of MNT 129 million.

6. “The Dalanzadgad CHPP” SOJSC were connected 01 October, 2018 to CRIPG and is being operated now parallel with the CRIPG. The interconnection of the plant with the central power system increases reliability of its operation by better utilization of the installed capacity and also enables to sustain financial condition as it become a participant of the electricity single-buyer model.